Customized injection moulding is commonly a specialised technique that will allow makers to generate plastic areas and factors meant to meet particular prerequisites. In contrast to normal injection moulding, which generally generates off-the-shelf objects, personalized injection moulding is about flexibility, precision, and innovation. It’s perfect for companies that have to have unique designs, components, or functionality in their products.

What's Tailor made Injection Moulding?

Customized injection moulding will involve setting up a bespoke mould and deciding on appropriate components to generate elements that are tailored having a consumer’s specs. This method commences with expose style section, generally working with Laptop or computer-Aided Structure (CAD) software, followed by the fabrication in the personalized Instrument or die. When the mould is manufactured, molten plastic is injected with it underneath cut-off dates, forming an exceptional variable that matches the framework exactly.

Great things about Custom Moulding

The main advantage of custom injection moulding is definitely the potential to supply highly specialised pieces. No matter whether it’s a complex shape, a robust tolerance, or perhaps a unique content prerequisite, This system can supply benefits here that off-the-shelf components are unable to match. It also provides superior repeatability, making sure Each and every portion is dependable in quality and gratification.

Custom made moulding might be scalable. After the initial mould is made, it can be used to produce countless numbers and even an unbelievable amount of similar elements effectively. This causes it to be a price-helpful Remedy for extended-phrase manufacturing, whether the upfront tooling price ranges are better.

Programs in Sector

Tailor made injection moulding is used across many industries, including automotive, professional medical, Digital units, and industrial gear. For example, a clinical gadget corporation may well have to have a plastic casing with designed-in antimicrobial Attributes, whilst an automotive producer might have higher-strength factors proof against warmth and chemical compounds.

Content Possibilities

One more advantage for custom injection moulding is the wide array of components available. From rigid ABS and affect-resistant Polycarbonate to adaptable TPU and chemical-resistant Nylon, clientele can pick out the plastic that matches their software.

Partnering with Experts

Functioning Using the knowledgeable injection moulding firm like Australian Consolidated Plastics aids to ensure that just about every stage—from design and prototyping to tooling and output—is managed with knowledge. Their capacity to give finish-to-conclusion help helps consumers decrease enhancement time and convey goods to market quicker.

Conclusion

Customized injection moulding might be a powerful producing solution which gives precision, versatility, and performance. Regardless of whether for prototyping or huge-scale manufacturing, it permits corporations to change innovative Thoughts into substantial-good quality plastic items personalized to their correct demands.

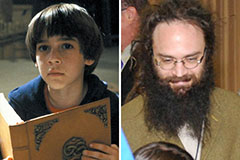

Barret Oliver Then & Now!

Barret Oliver Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!